When looking at the characteristics of synthetic flooring such as sheet vinyl for a new sports surfacing project, many different factors have to be considered as they can affect the performance and the functionality of the floor covering. That is why there are universal standards with specialized testing methods to evaluate the many particular aspects of the layers that make up the resilient sports floor.

One of the most essential aspects of synthetic flooring is the quality of the wear layer. The purpose of this top layer is to protect the appearance, pattern, and colouring of the floor. Furthermore, the finish of the wear layer affects the texture of the surface which influences the floor’s performance. These aspects clearly illustrate why it would be desirable for this portion of the flooring to be as durable as possible.

The complication

There is a difficulty that presents itself when the visual pattern of the flooring system is incorporated within the wear layer. This, therefore, reduces the actual portion dedicated to wearing before compromising the design and its life cycle. Aside from the unattractiveness, the performance of the flooring when playing will be directly affected when the surface has been worn through to the coloration and pattern. This is why top-quality manufacturers will adopt the practice of applying the full wear layer above the design, ensuring the protection of its colour and motif underneath.

It is also important to note that the physical texture of the wear layer can also cause certain problems. The sports flooring industry refers to this texture as linear embossing, also called five o’clock shadow. See our blog article for more detail.

Industry-wide standards

The resilient floor covering standards as per ASTM are there to help people build their knowledge, particularly to make a well-informed decision when comes the time to choose a sports floor. These universal standards are instrumental in specifying and analyzing the flooring’s properties. The results of the product testing make it possible to establish the appropriate installation procedures of a flooring, as well as ensure its strength, durability, and safety towards utilization.

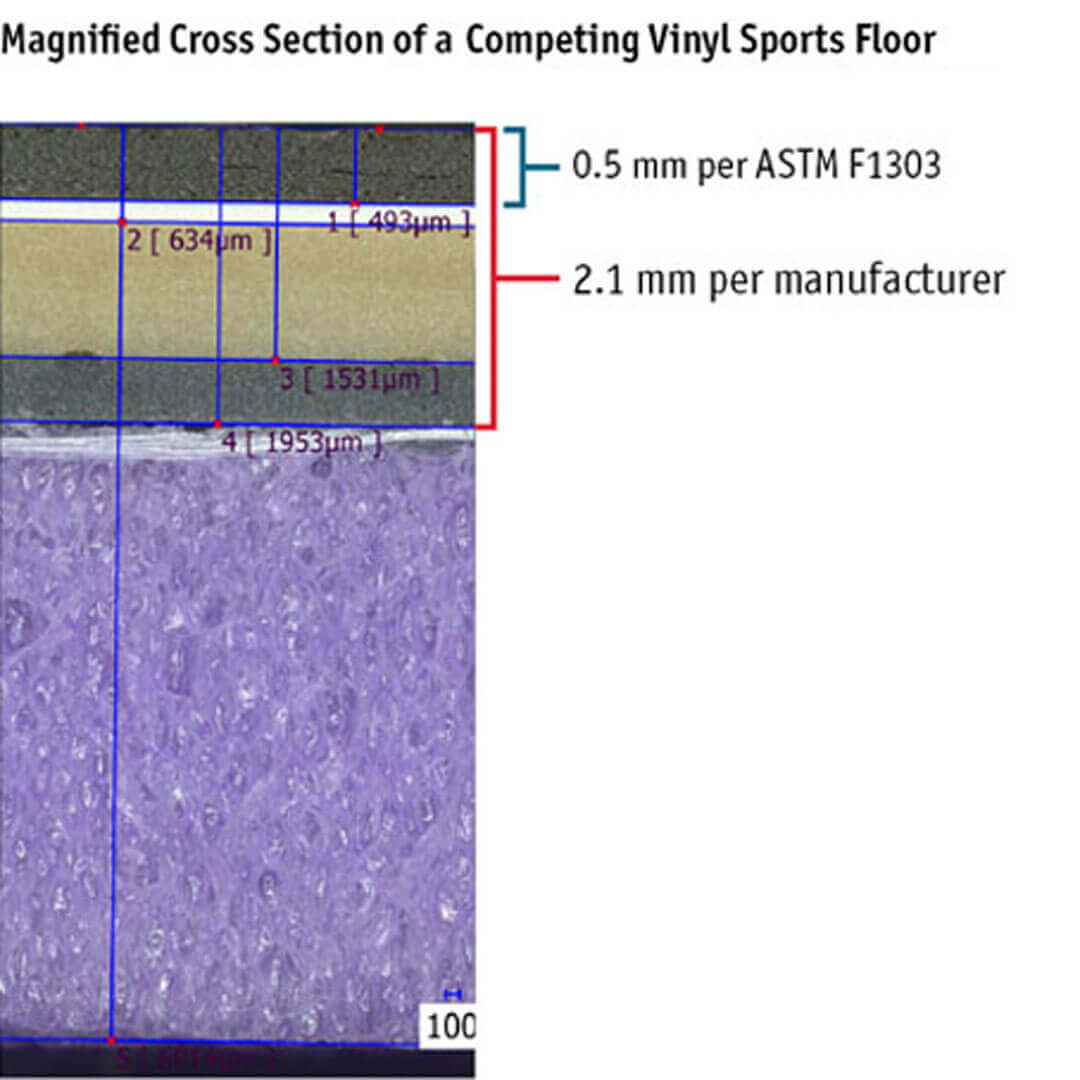

Unfortunately, there are some manufacturers and/or distributors who choose to avoid industry testing standards to hide the fact that the tests revealed a sub-standard product. This creates hurdles to overcome when undergoing the process of choosing flooring that meets expectations, especially when looking for a product with a well-designed and resistant wear layer.

We understand the intensive use sports flooring will take, this is why we ensure that our products meet the highest industry standards of wear layer technology. We also know that a long-lasting floor makes your investment go a long way.

To know more about wear layers in greater detail, please see an article about “Defining wear layers” from our Tarkett Sports supplier: https://www.tarkettsportsindoor.com/sports-flooring-guide/defining-wear-layers/